High-Speed Rail C4 AI Vision Inspection Solution

Industry Pain Points

-

Labor-Intensive Manual Correction for Defect Localization

GPS positioning inaccuracies lead to incorrect pole number data in raw analysis results, requiring technicians to manually verify and correct each error by cross-referencing physical pole ID plates in images - a time-consuming and inefficient process. -

Data-Deficient Monitoring Plans

Current maintenance schedules for seasonally recurring or environment-dependent defects rely solely on historical experience, lacking empirical data support for high-risk area identification - resulting in suboptimal monitoring coverage. -

Reactive Equipment Maintenance Without Predictive Capabilities

The existing repair mechanism fails to track defect progression patterns, forcing reactive maintenance approaches that increase the probability of severe failures occurring.

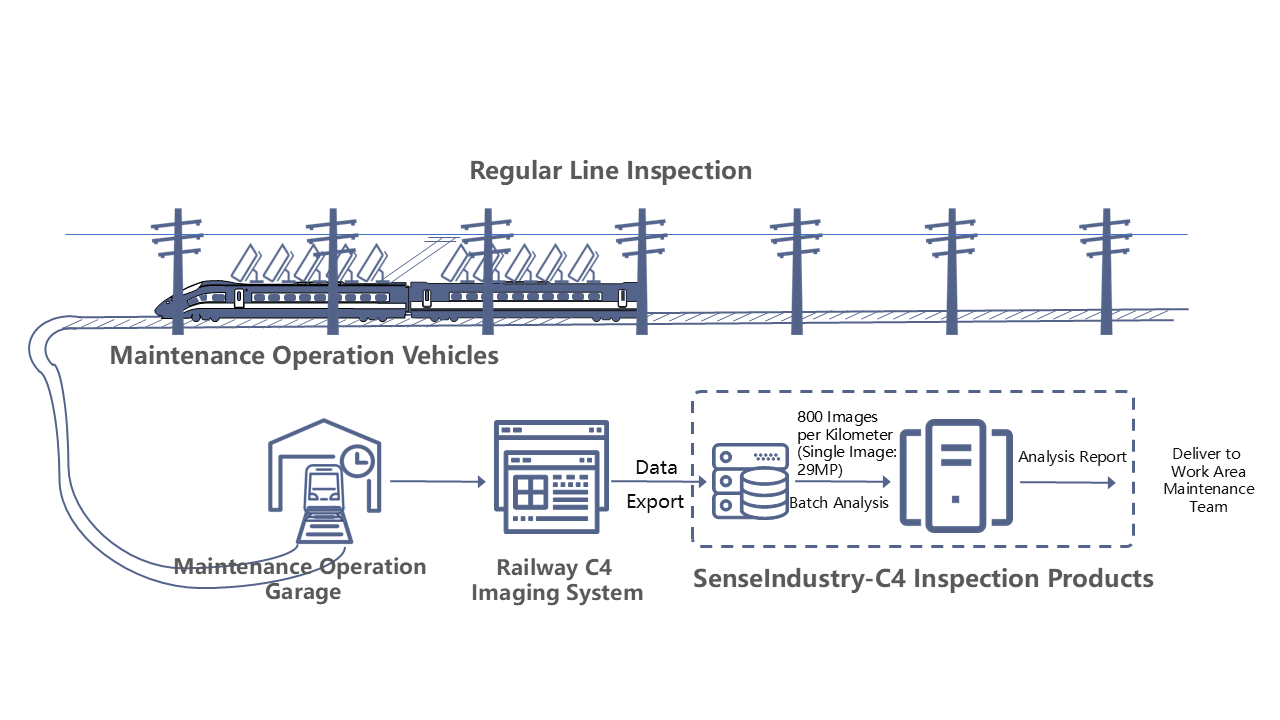

Solution Overview

High-Speed Rail C4 AI Vision Inspection Solution

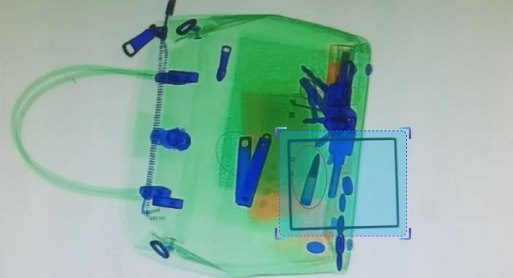

In the railway 6C inspection system, inspection scenarios such as C2, C3, and C4 face significant efficiency bottlenecks in manual image review—processing only 3 kilometers of track images and 3,000 high-resolution photos per day, resulting in lengthy workflows and delayed defect identification.

To address this industry pain point, SenseTime presents the High-Speed Railway C4 Intelligent Inspection AI Vision Solution. Powered by advanced AI image recognition technology, it enables:

Fine-grained intelligent analysis of massive image datasets.

Significant improvement in defect detection efficiency.

Rapid localization and resolution of potential hazards.

This solution builds a smart defense system for railway safety and stable operation, empowering maintenance departments with accelerated hazard identification and response capabilities.

Solution Highlights

Application Value

-

36-Hour Inspection Time Savings per Session

Achieves precise defect localization through pole number recognition and auto-correction. Case study: Zhangda Passenger Dedicated Line 90% of incorrect pole numbers previously required manual correction. OCR-based recognition + AI-assisted correction enables efficient defect pinpointing. -

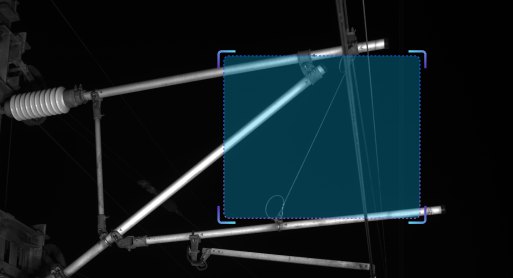

4-5 Days Expert Time Savings per Inspection

Supports maintenance planners in developing: Seasonal priority control plans. Regional risk-focused inspection strategies. Example applications: Nest-shaped structure regional analysis. Contaminated insulator high-incidence area identification. -

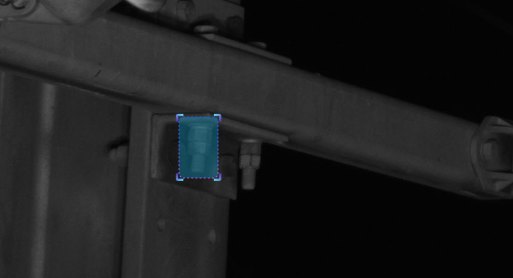

80% Reduction in Failure Rates

CBM-based condition monitoring identifies equipment degradation patterns. Case study: Dropper wire fracture prevention. Degradation cycle-based maintenance reduces failure rates by ≥80%.