Industrial Defect Detection

Algorithm Introduction

Industrial defect detection algorithms serve as a cornerstone technology in smart manufacturing and industrial automation, finding extensive applications in product quality control, production process optimization, and other domains. With the advancement of deep learning, computer vision, and sensor technologies, these algorithms have achieved remarkable progress in precision, efficiency, and adaptability. Depending on specific defect detection requirements, appropriate algorithmic approaches—including classification, object detection, segmentation, and multimodal fusion techniques—are selectively employed.

Application Value

-

Electronics Manufacturing

PCB Defect Detection: Identifies soldering defects, short circuits, and missing components. Chip Packaging Inspection: Detects scratches and contaminants. -

Metal Processing

Steel Surface Defect Analysis: Identifies cracks and dents. Aluminum Alloy Plate Inspection: Detects surface imperfections -

Automotive Manufacturing

Weld Quality Assessment: Locates weld seam defects. Coating Defect Detection: Identifies paint imperfections. -

Food & Packaging

Beverage Label Inspection: Detects label defects on bottled drinks. Foreign Object Detection: Identifies contaminants in food products. -

New Energy Industry

Solar Panel Inspection: Detects micro-cracks and surface contaminants. Lithium Battery Electrode Testing: Identifies defects in battery electrodes. -

Rail Transit

Rail Surface Defect Detection: Identifies scratches and cracks on rail tracks.

FAQ

-

Algorithm AccuracyAll algorithms published on the website claim accuracies above 90 %. However, real-world performance drops can occur for the following reasons:

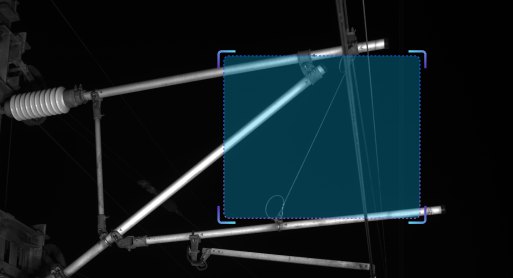

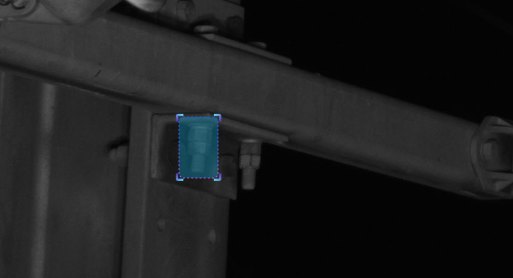

(1) Poor imaging quality, such as

• Strong light, backlight, nighttime, rain, snow, or fog degrading image quality

• Low resolution, motion blur, lens contamination, compression artifacts, or sensor noise

• Targets being partially or fully occluded (common in object detection, tracking, and pose estimation)

(2) The website provides two broad classes of algorithms: general-purpose and long-tail (rare scenes, uncommon object categories, or insufficient training data). Long-tail algorithms typically exhibit weaker generalization.

(3) Accuracy is not guaranteed in boundary or extreme scenarios.

-

Deployment & InferenceWe offer multiple deployment formats—Models, Applets and SDKs.

Compatibility has been verified with more than ten domestic chip vendors, including Huawei Ascend, Iluvatar, and Denglin, ensuring full support for China-made CPUs, GPUs, and NPUs to meet high-grade IT innovation requirements.

For each hardware configuration, we select and deploy a high-accuracy model whose parameter count is optimally matched to the available compute power.

-

How to Customize an AlgorithmAll algorithms showcased on the website come with ready-to-use models and corresponding application examples. If you need further optimization or customization, choose one of the following paths:

(1) Standard Customization (highest accuracy, longer lead time)

Requirements discussion → collect valid data (≥1 000 images or ≥100 video clips from your scenario) → custom algorithm development & deployment → acceptance testing

(2) Rapid Implementation (Monolith:https://monolith.sensefoundry.cn/)

Monolith provides an intuitive, web-based interface that requires no deep AI expertise. In as little as 30 minutes you can upload data, leverage smart annotation, train, and deploy a high-performance vision model end-to-end—dramatically shortening the algorithm production cycle.