SenseIndustry-C4

Product Overview

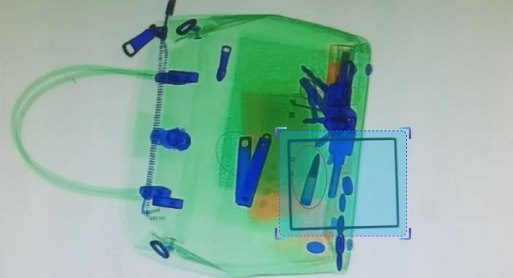

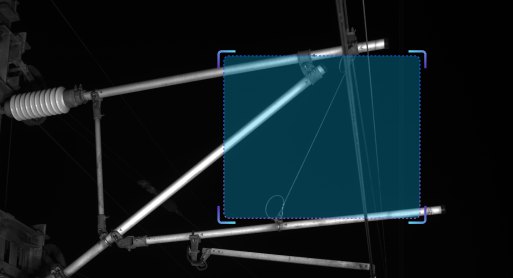

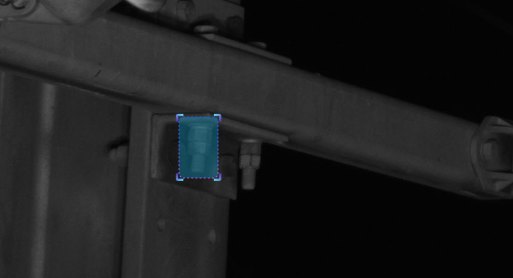

Powered by deep learning technology, this solution precisely identifies components within overhead contact line structures in images, analyzing defects in key parts such as hangers, insulators, bolts/nuts, and cotter pins. Through intelligent inspection, it significantly reduces manual review workload for inspectors.

Product Features

-

Data Archive Management

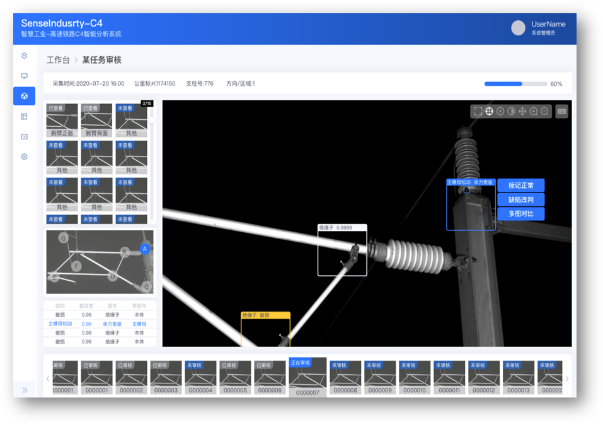

Comprehensive data archive administration; Collected data quality verification; Camera-specific analysis by device ID. -

Review Workflow System

Flexible review processes supporting: • Random defect sampling, • Full-volume rechecking, • Differential review. Automated merging of duplicate defects from multi-camera captures; Data aggregation and visualization for: • Archive analysis results, • Manual review findings. -

Defect Database Integration

Conditional query capabilities, Defect record viewing, Database export functionality.

Product Highlights

-

Precision Data Labeling Management

Implement hierarchical tagging system for C4 inspection vehicle data: • Route-based classification, • Station area segmentation, • Directional labeling (uplink/downlink) -

AI-Assisted Efficient Inspection

Automated defect detection with human-in-the-loop verification, Significantly accelerates image review workflow -

Algorithm-Driven Accurate Judgment

Multi-level positioning technology combined with proprietary algorithms, Enhanced defect identification accuracy, Supports intelligent multi-image cross-comparison

Application Value

-

Intelligent and Efficient Drawing Review

Leverages deep learning technology to rapidly identify overhead contact line components and defects, enabling power supply maintenance personnel to efficiently screen large-format images for potential issues, significantly improving work efficiency. -

Precise Detection for Hazard Elimination

Specializes in detecting defects in critical fastening components such as bolts, nuts, and cotter pins, as well as common environmental hazards like bird nests and branch obstructions that frequently impact power supply safety. Overcomes the limitations of manual inspection caused by human experience constraints and fatigue, enhancing both the completeness and standardization of defect detection.